Essential Roof Installation Safety Tips to Know Before Starting Your Project

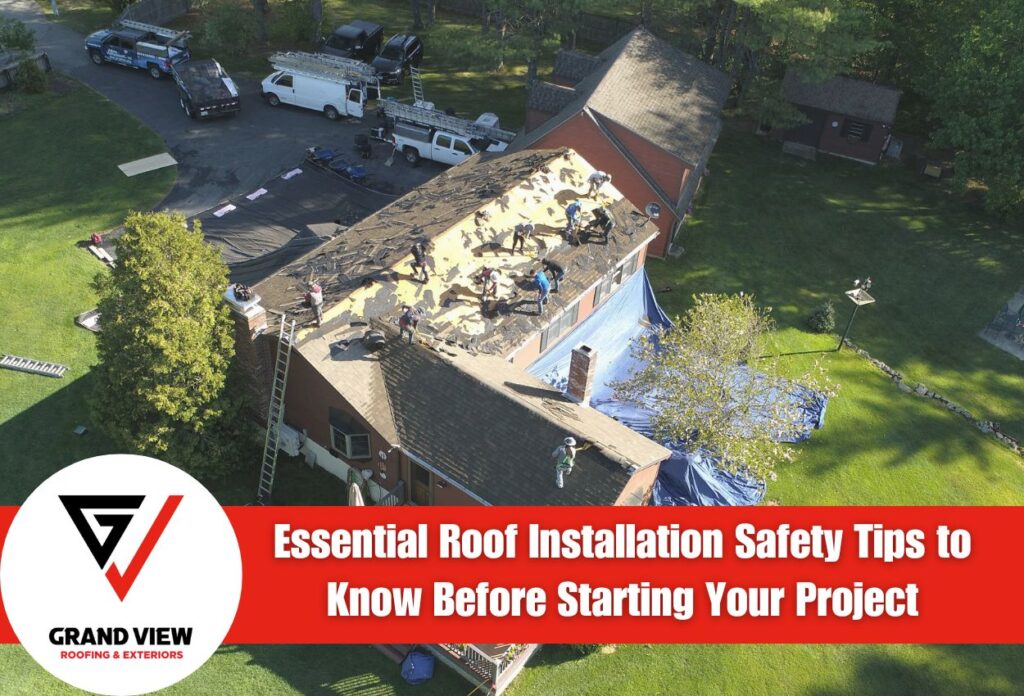

Roof installations come with significant hazards that require comprehensive safety planning before any work begins. Professional roofers face multiple risks, including falls from heights, equipment failures, and weather-related dangers that can result in serious injuries or fatalities. Roof installation safety tips are the foundation of successful roofing projects and protect workers from preventable accidents.

Effective safety preparation involves a systematic risk assessment that identifies potential roof installation hazards specific to each project. Every roofing job has challenges based on factors such as roof pitch, building height, surrounding obstacles, and structural conditions. Professional contractors must evaluate these variables to develop appropriate safety protocols before workers step onto any roof surface.

Weather conditions play a critical role in determining when roof installation work can proceed safely. High winds, rain, ice, and extreme temperatures create dangerous working conditions that compromise both worker safety and installation quality. Understanding proper timing considerations and weather evaluation procedures helps prevent accidents while ensuring optimal installation conditions.

Roofing safety equipment and fall protection systems should be accounted for during the planning phase. Ladder safety protocols, personal protective equipment requirements, and emergency response procedures must be established before work commences. These safe roofing practices create the framework for successful project completion while protecting workers and anyone below.

Safety Equipment and Personal Protective Gear for Roof Installations

Personal protective equipment is the primary defense against roof installation hazards and should be chosen based on specific job requirements. Safety harnesses are one of the most crucial components of fall protection systems, designed to distribute impact forces across the body during potential falls. Full-body harnesses with multiple attachment points provide superior protection compared to basic waist belts and must meet current safety standards for maximum effectiveness.

Hard hats protect workers from falling debris and overhead hazards commonly encountered during roofing projects. Quality helmets feature impact-resistant shells and shock-absorbing suspension systems that reduce injury severity from dropped tools or materials. Non-slip footwear with aggressive tread patterns enhances traction on various roofing surfaces and prevents dangerous slips during installation activities.

Specialized roofing safety equipment addresses specific challenges during installation. Safety rope systems and anchor points create secure attachment opportunities for harnesses while allowing necessary mobility across roof surfaces. Roof brackets and toe boards provide stable working platforms that reduce fatigue and improve installation accuracy throughout extended work periods.

Equipment for safe ladder use includes stabilizer bars and tie-down systems that prevent dangerous movement during use. These roof safety components work together to create comprehensive protection systems that address multiple hazards. Equipment maintenance and testing ensure reliable performance when protection systems are needed most.

Proper Ladder Setup and Safe Access Techniques for Roofing Projects

Correct ladder positioning is the basis of safe roof access and requires precise angle calculations to ensure stability throughout the installation process. The optimal ladder angle follows the four-to-one rule, where the base distance from the building equals one-fourth of the ladder’s working height. This positioning creates approximately a 75-degree angle that balances stability with functional access to roof surfaces while minimizing the risk of backward tipping or sliding.

Securing methods for ladders involve multiple attachment points that stop lateral movement and base slippage during climbing activities. Ladder stabilizers extend beyond the roof edge to distribute weight across larger surface areas while preventing damage to gutters and siding materials. Ground-level securing techniques include stakes, sandbags, or having a spotter maintain ladder stability during critical access periods when roof installation safety becomes most important.

Safe climbing techniques include three points of contact, where hands and feet remain connected to ladder rungs throughout the ascent and descent process. Weight distribution practices require climbers to keep their belt buckle positioned between the ladder rails, preventing dangerous overreaching that can cause falls. Tools and materials should be lifted separately using rope systems rather than carried during climbing to maintain proper balance and grip strength.

These safe roofing practices reduce ladder-related accidents that account for significant injury rates in roofing operations. Proper ladder setup procedures address common roof installation hazards while establishing reliable access points for subsequent fall protection systems and daily work activities.

Fall Protection Systems and Harness Safety During Roof Work

Fall protection systems provide critical safety barriers that prevent roofing workers from experiencing dangerous falls during installation activities. Three primary protection categories include guardrails, safety nets, and personal fall arrest systems that address different roof configurations and project requirements. Guardrail systems create physical barriers along roof edges and openings, offering passive protection that requires no worker interaction once installed.

Safety nets serve as collective fall protection systems positioned beneath work areas to catch falling workers or debris. These systems prove particularly effective for large roof surfaces where individual harness systems might limit mobility or productivity. Personal fall arrest systems combine harnesses with anchor points and connecting devices to stop falls in progress while minimizing impact forces on the worker’s body.

Preproject harness fitting ensures that fall protection roofing equipment functions correctly during emergency situations. Chest straps should sit mid-chest level, while leg straps should sit snugly around the upper thighs without restricting circulation. Dorsal D-rings must align between the shoulder blades to distribute forces properly during fall arrest events, and all buckles require secure engagement without overtightening that causes discomfort.

Anchor point selection should include evaluating structural capacity and positioning relative to work areas. Suitable anchor points must support minimum loads of 5,000 pounds per attached worker while positioning to minimize fall distances and swing hazards. Regular inspection procedures for roofing safety equipment include checking harnesses for cuts, burns, or worn areas, testing buckle functionality, and verifying anchor point integrity before each use period.

Identifying and Managing Common Roofing Installation Hazards

Roofing installation presents numerous structural hazards that require immediate identification and careful management to protect workers throughout the project. Weak roof decking represents one of the most dangerous structural concerns, as deteriorated or damaged sheathing may collapse under worker weight without warning. Professional roofers must thoroughly inspect decking materials before beginning installation work, looking for signs of rot, water damage, or previous repairs that compromise structural integrity.

Unstable surfaces often extend beyond obvious decking problems to include loose flashing, compromised supports, and temporary materials left from previous work. These conditions can shift unexpectedly under weight, causing falls or equipment damage that endangers entire work crews. Systematic surface evaluations help identify these risks before workers commit their full weight to questionable areas.

Electrical dangers pose serious threats during roofing projects, particularly when working near power lines, electrical equipment, or during solar panel installations. Overhead power lines require minimum clearance distances that vary based on voltage levels, while roof-mounted electrical systems need specialized knowledge to avoid electrocution risks. Understanding electrical safety protocols prevents potentially fatal accidents during routine installation activities.

Environmental hazards, including construction debris, accumulated leaves, and moisture, create slippery surfaces that compromise footing and increase fall risks. Morning dew, recent precipitation, and seasonal ice formation transform normally stable roofing surfaces into dangerous working conditions. These roofing safety equipment considerations require continuous monitoring throughout the project, as weather conditions change rapidly and affect worker safety significantly.

Safe Work Practices and Team Communication During Installation

Effective team communication is crucial for safe roofing operations and requires established protocols that keep all crew members informed about changing conditions and potential hazards. Clear communication systems must address both routine coordination needs and emergency situations that need immediate response from multiple team members. Radio communication or designated signal systems allow workers to maintain contact across large roof areas where verbal communication becomes difficult due to distance or ambient noise.

Work zone boundaries create defined safety perimeters that protect both roofing crews and ground personnel from falling debris and equipment hazards. These boundaries should extend beyond the roof perimeter in all directions, with additional clearance for multi-story buildings or windy conditions. Signage and barrier systems alert pedestrians and other workers to active roof installation hazards while preventing unauthorized access to dangerous areas beneath active work zones.

Material handling techniques during roof installation require coordinated lifting procedures that prevent back injuries and dropped object accidents. Team lifting protocols for heavy materials such as shingle bundles or metal panels ensure proper weight distribution while reducing individual strain on workers. Mechanical lifting equipment, including hoists or conveyors, eliminates many manual handling risks while improving efficiency during material placement.

Tool management systems prevent accidents caused by dropped objects that can injure ground personnel or damage property below work areas. Tethering systems for hand tools, secure storage containers, and designated tool zones help maintain organization while preventing dangerous falling objects. These safe roofing practices require consistent application throughout the project, as tool-related accidents often occur during routine activities when workers become complacent about roofing safety.

Emergency Procedures and Accident Prevention Strategies for Roofing Teams

Emergency response planning requires detailed procedures specifically designed for roofing accident scenarios, including height-related injuries and rescue operations. Roofing teams should have clear protocols for falls, equipment failures, and weather emergencies before beginning any installation work. These emergency procedures should include immediate response steps, communication protocols, and evacuation routes that account for the elevated work environment and limited access points typical in roofing projects.

Rescue procedures during roof installations should balance rapid response with rescuer safety. Team members must understand proper techniques for approaching injured workers without creating additional victims, particularly when dealing with fall protection failures. Emergency communication systems should include direct contact methods for emergency services, company supervisors, and medical personnel who understand roof installation hazards and appropriate treatment protocols.

First aid training specific to roofing injuries addresses common accident scenarios, including minor falls, cuts from sharp materials, heat-related illnesses, and equipment-related injuries. Team leaders should maintain current certification in workplace first aid and CPR, with emphasis on trauma care appropriate for height-related accidents. Emergency supply kits positioned at ground level and on roof surfaces ensure immediate access to critical medical supplies when response time is crucial for injury outcomes.

Proactive safety management through regular training prevents accidents by maintaining crew awareness of ladder risks and proper use of roofing safety equipment. Worker safety meetings, regular equipment inspections, and skills assessments help identify knowledge gaps before they result in accidents. These safe roofing practices create a culture of continuous improvement where accident prevention becomes an integral part of daily operations rather than an afterthought during emergency situations.

Ensure Your Safety with Expert Roof Installation Services

If you’re planning a roofing project, the importance of adhering to strict safety protocols cannot be overstressed. At Grand View Roofing & Exteriors, we follow comprehensive roof installation safety tips and use state-of-the-art roofing safety equipment. Our team is trained in the latest ladder safety techniques and fall protection measures to ensure a secure installation process.

Don’t compromise on safety. Contact Grand View Roofing & Exteriors today at (856) 305-9883 to schedule a consultation. Let our professionals handle your roofing needs safely and efficiently. Your protection is our top priority!

Call Us Today - (856) 305-9883

Call Us Today - (856) 305-9883